Marine Engineering: Essential Concepts for Aspiring Professionals

Marine engineering is a specialized field that focuses on the design, construction, operation, and maintenance of various systems and machinery used in the marine industry. This includes shipbuilding, offshore platforms, and other marine structures. The discipline encompasses various key aspects, such as marine propulsion technologies, onboard systems and component management, and safety and regulatory compliance.

A marine engineer is responsible for designing and developing the essential systems and technologies utilized in marine vessels and structures. This involves integrating various components, such as propulsion systems, electrical and electronics systems, and specialized technologies for specific applications. Additionally, marine engineers work closely with other professionals in the industry to ensure the safe and efficient operation and maintenance of marine machinery and equipment.

Key Takeaways

- Marine engineering focuses on designing and developing systems used in marine vessels and structures

- Essential aspects include propulsion technologies, onboard system management, and safety compliance

- Marine engineers collaborate with other professionals to ensure efficient operation and maintenance of marine machinery

Fundamentals of Marine Engineering

Marine Engineering is a specialized field of engineering that deals with the design, construction, and maintenance of ships, submarines, and other marine vessels. It incorporates various principles of mechanics, physics, materials science, and fluid mechanics to create efficient and reliable marine systems. In this section, we will discuss the core aspects of marine engineering, including the principles of marine mechanics, materials and their properties, and marine engineering systems.

Principles of Marine Mechanics

Marine mechanics is a sub-discipline of engineering that focuses on the mechanical aspects of marine vessels, such as the forces acting on them and their behavior in response to those forces. One key concept in marine mechanics is hydrodynamics, which is the study of fluid motion in relation to marine structures. It involves the understanding of concepts such as buoyancy, drag, and lift, which play a crucial role in designing efficient marine vessels.

Another important aspect of marine mechanics is structural analysis, which ensures the integrity and stability of the vessel. Marine engineers must consider factors such as the distribution of loads, stress concentration, and fatigue to design durable structures.

Materials and Their Properties

Choosing the right materials for constructing a marine vessel is critical, as they must be able to withstand not only the mechanical stresses but also the harsh marine environment. Typical materials used in marine engineering include steel, aluminum, and composites. Marine corrosion is a significant concern, as materials are often used to their engineering limits in marine situations.

Steel is a commonly used material due to its strength and durability. However, it is susceptible to rust and corrosion, requiring regular maintenance and protective coatings. Aluminum is another popular choice, as it is lightweight, corrosion-resistant, and easy to fabricate. Composites, such as fiberglass and carbon fiber, offer many advantages, including resistance to corrosion, high strength-to-weight ratio, and flexibility in design.

Marine Engineering Systems

Marine engineering involves the design and integration of various systems that work together to ensure the proper functioning and safety of a marine vessel. Some of these systems include:

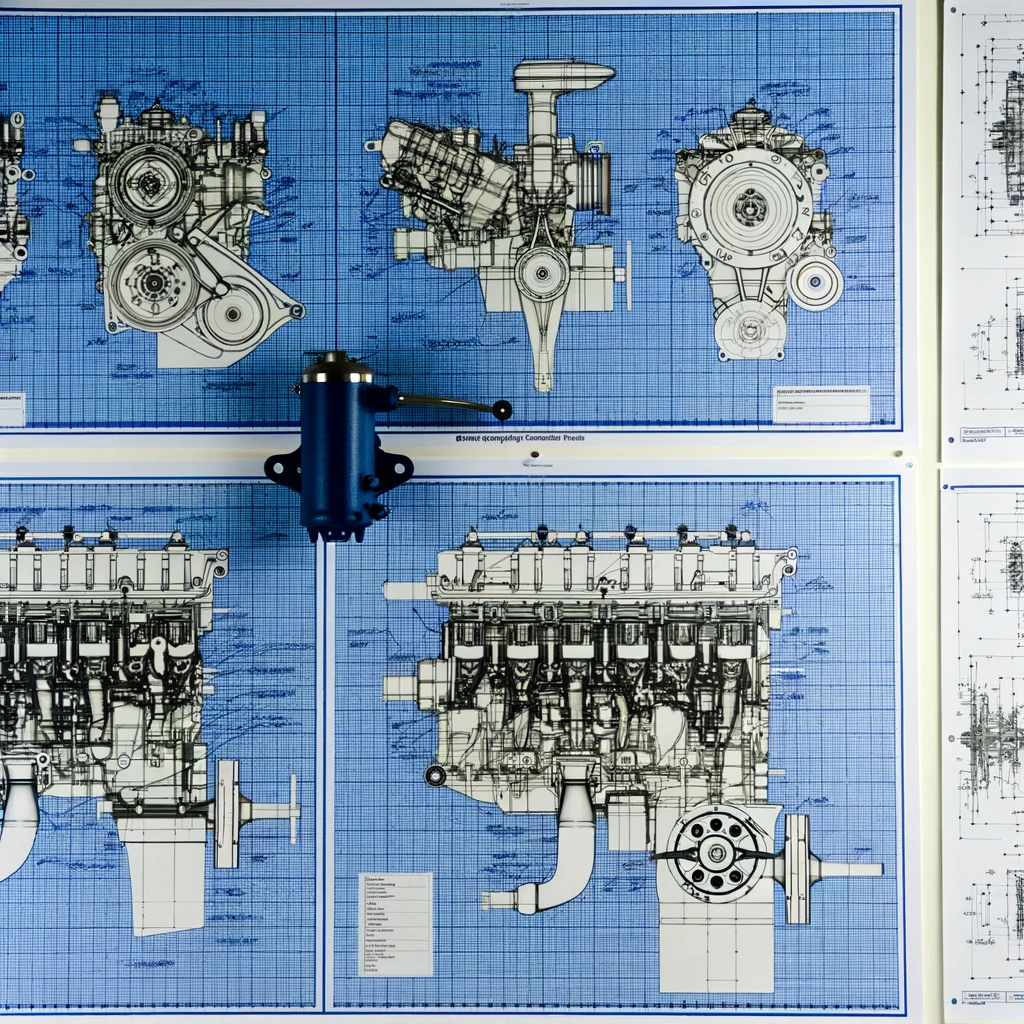

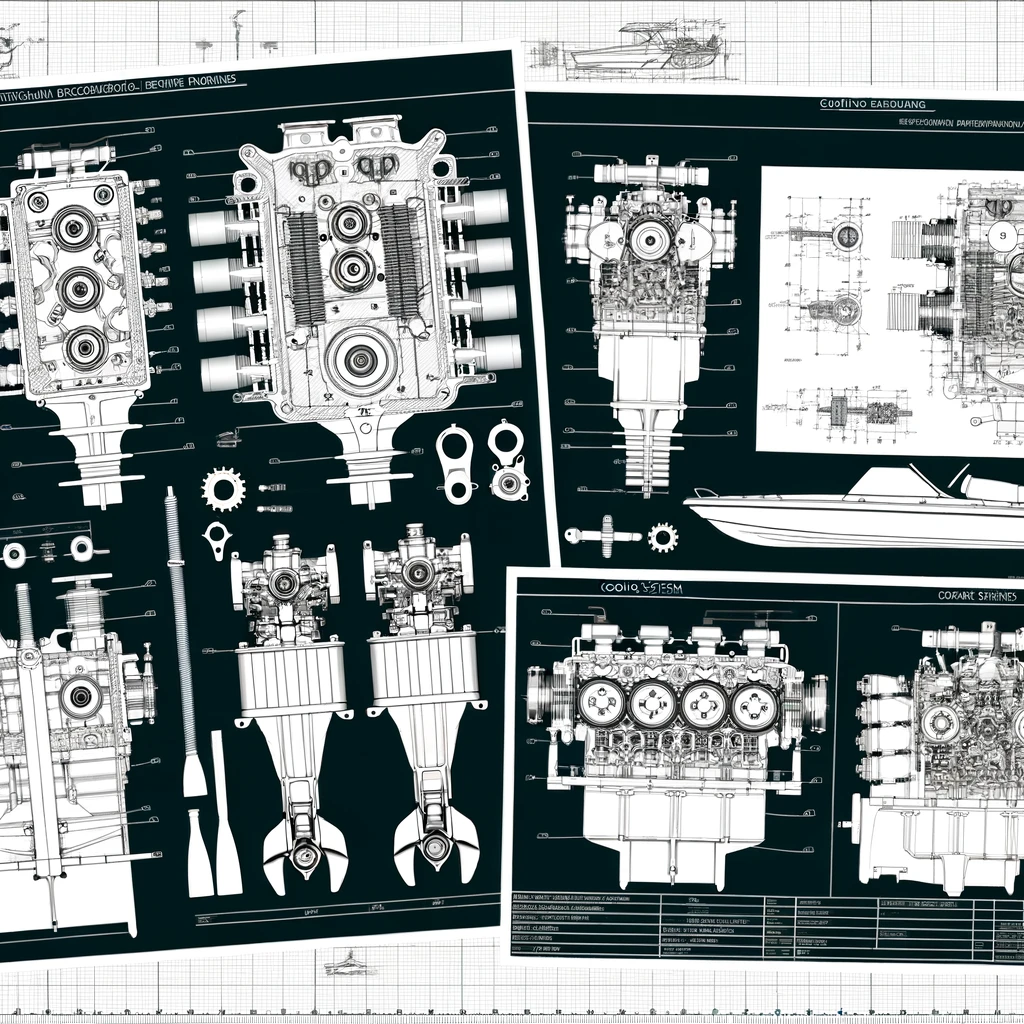

- Propulsion systems: Marine engineers are responsible for designing propulsion systems that convert energy into motion. These systems can range from traditional diesel engines to advanced electric and hybrid systems.

- Control systems: Marine vessels require sophisticated control systems to monitor and control various aspects of their operation, such as navigation, propulsion, and power generation. Marine engineers must design these systems to be reliable and efficient.

- Electrical systems: Marine vessels rely on electrical systems for power distribution, lighting, and communication. Marine engineers need to design robust and safe electrical systems that can withstand the harsh marine environment.

In conclusion, marine engineering is a multi-faceted field that incorporates principles from various branches of engineering, such as mechanics, science, physics, materials, hydrodynamics, fluid mechanics, and materials science. It plays a crucial role in the design, construction, and maintenance of various marine vessels, ensuring their efficiency, safety, and reliability.

Marine Propulsion Technologies

Mechanical Propulsion Systems

Marine propulsion systems have evolved significantly over the years, and mechanical systems continue to play a crucial role. These systems primarily rely on the combustion of fossil fuels like diesel or heavy fuel oil to generate power and propel the vessel. One popular method is through diesel engines. Various types of diesel engines exist, including two-stroke and four-stroke engines, each offering unique advantages in terms of efficiency, size, and power output.

Mechanical propulsion can also involve the use of gas turbines. Though less common than diesel engines, gas turbines offer higher power density, enabling a smaller footprint and lower overall weight. They are primarily used in high-performance naval vessels, where quick acceleration and top speed are essential1.

The energy generated by these engines is transmitted to the propellers through a complex system consisting of gearboxes, shafts, and bearings, which convert the engine's torque and rotational speed into thrust. Propeller design has a significant impact on propulsion efficiency, with advancements in materials and manufacturing techniques leading to improved hydrodynamic properties and reduced noise and vibration2.

Electrical and Hybrid Systems

With growing concerns over environmental impact and a push for greener technologies, the marine industry has been exploring alternative, more sustainable propulsion options. One such development is the use of electrical propulsion. Electrical systems involve converting the energy generated by a power source (typically a diesel generator or fuel cell) to electrical energy, which is then delivered to the electric motors3. The electric motors, in turn, power the propellers, providing propulsion. Electrical propulsion systems offer several benefits, including higher efficiency, lower noise, and improved maneuverability.

Hybrid propulsion systems combine the strengths of both mechanical and electrical systems. In a hybrid setup, either the mechanical or the electrical system can propel the vessel, allowing for greater flexibility in operations4. For instance, at low speeds or when maneuvering in port, the vessel may rely entirely on electrical power to reduce emissions and noise levels. High-speed operations or long-range missions may require the use of the integrated mechanical system for increased power and endurance.

Design and Construction of Marine Vessels

Naval Architecture

As an integral part of marine engineering, naval architecture plays a vital role in the design and construction of marine vessels. Naval architects are responsible for the overall development of ships and boats, taking into account factors such as hydrodynamics, stability, and maneuverability. Working closely with marine engineers, they ensure that vessels are not only efficient in their functionality but also adhere to safety standards and regulations. Key aspects of ship design include the development of hull shapes and the implementation of advanced materials to optimize the vessel's performance in various marine environments.

Shipbuilding Process

The construction of marine vessels is a complex and meticulous process, involving several stages that demand specialized expertise and advanced technology. Here is a brief overview of the typical shipbuilding process:

- Design Phase: The naval architect, along with a team of marine engineers, designs the vessel considering various factors, such as ship type, size, and functionality. At this stage, the vessel's hull shape, dimensions, and other features are virtually developed using computer-aided design (CAD) tools.

- Material Selection & Preparation: Choosing the right materials is essential to ensure the boat's structural integrity and durability. Steel is the most common material used in shipbuilding, but other materials, such as aluminum, fiberglass, and composite materials, can also be employed. These materials are cut, shaped, and prepared for assembly according to the design plans.

- Assembly & Welding: The various components, including the hull, deck, and superstructure, are assembled in dry docks or slipways. Welding and other joining methods are used to construct the vessel's framework, which provides strength and stability.

- Outfitting & Systems Installation: This stage involves the installation of equipment and systems essential to the operation of the vessel, such as engines, electrical systems, and propellers. The ship's interior components, such as cabins, galleys, and control stations, are also fitted during this phase.

- Finishing & Inspection: Once the vessel is completely constructed, it undergoes a series of tests and quality-control inspections to ensure safety, functionality, and compliance with regulations. After successful inspections, the vessel can be painted, given a final cleaning, and prepared for launch.

The design and construction of marine vessels in the modern age demand a combination of expertise, advanced technology, and an adherence to stringent safety and environmental standards. As a result, shipbuilders and naval architects continuously work together to develop more efficient, safe, and environmentally friendly vessels for various maritime purposes.

Operation and Maintenance of Marine Machinery

Equipment Handling

In marine engineering, handling equipment forms a crucial part of the smooth operation of a ship's machinery. The engine room contains various machinery such as engines, pumps, and other systems that require proper handling to ensure efficiency and prevent breakdowns. The process of equipment handling generally consists of operating machinery, monitoring their performance, and addressing any issues that arise during operation. Familiarizing oneself with the common failures of marine machinery and equipment can provide valuable insight into handling procedures.

Some important guidelines for equipment handling include:

- Following the manufacturer's instructions for operation

- Ensuring that the equipment is operated within its specified capacity

- Monitoring the equipment for signs of wear or damage

- Maintaining a strict schedule for regular inspections and maintenance

Routine Maintenance and Repair

Routine maintenance and repair are essential in preserving the functionality of marine machinery. Regular maintenance helps to prevent costly breakdowns and ensures the long-term efficiency of the equipment. Implementing a maintenance management system can provide structure and improve the overall maintenance process of marine machinery systems.

Essential maintenance tasks include:

- Lubrication - Regularly checking and maintaining proper lubrication levels for moving parts is crucial in reducing friction and wear.

- Cleaning - Keeping machinery clean prevents the build-up of dirt, debris, and other harmful substances that can interfere with the equipment's operation.

- Inspection - Regular visual inspections can help identify any damage, wear, or potential issues that may arise in the future.

- Replacement of worn parts - Timely replacement of worn or damaged components ensures continuous and efficient operation of the machinery.

When issues do arise with marine machinery, timely repairs are critical to minimize downtime and maintain the functionality of the system. Ship engineers should have a comprehensive understanding of the machinery and components they work on, enabling them to diagnose and address issues quickly. Additionally, utilizing decision-making support tools, as mentioned in the research on marine maintenance systems, can further enhance maintenance optimization.

In conclusion, the proper operation and maintenance of marine machinery are essential for efficient ship functioning. Adherence to equipment handling guidelines and routine maintenance practices, combined with timely repairs, ensures the longevity and performance of marine machinery systems.

Career and Professional Development in Marine Engineering

Educational Pathways

Marine engineering is a promising profession with various career opportunities in the maritime industry. To become a marine engineer, one must follow a specific educational pathway. Typically, a bachelor's degree in marine engineering, naval architecture, or a related field is required. Some universities offer specialized programs, such as the Ocean University of China, focusing on specific aspects of ship engineering.

The curriculum for marine engineering programs covers essential disciplines, including:

- Mathematics: Calculus, differential equations, and linear algebra

- Physics: Mechanics, fluid dynamics, and thermodynamics

- Engineering Design: Ship structure, propulsion systems, and control systems

Throughout their education, marine engineers may participate in project-based learning to develop hands-on experience and practical skills. They also need solid communication and teamwork abilities, as they often collaborate with other engineering professionals, such as naval architects, mechanical engineers, and electrical engineers.

Certifications and Licenses

After completing their bachelor's degree, aspiring marine engineers may pursue certifications and licenses to enhance their career prospects. One of the most common certifications is the Engineering License issued by a country's maritime authority. This allows marine engineers to work on various types of vessels, including commercial ships, offshore platforms, and military vessels.

There are several levels of engineering licenses, ranging from Junior Engineer to Chief Engineer, which require different levels of experience and qualifications. Obtaining these licenses often involve meeting both educational and training requirements, as well as passing a comprehensive examination.

In addition, marine engineers may also seek professional certifications from industry-specific organizations, such as the Society of Naval Architects and Marine Engineers or the Institute of Marine Engineering, Science, and Technology. These certifications demonstrate a marine engineer's expertise in a specific area or specialization and can help them advance in their career.

By following the educational and professional development pathways outlined above, marine engineers can build a fulfilling and successful career in this vital industry.

Electrical and Electronics Engineering in Marine

Control Systems

Electrical and electronics engineering play a crucial role in marine engineering, particularly in control systems. These systems manage and automate various aspects of ships and offshore platforms, such as propulsion, power distribution, and safety systems. Control systems in marine environments often rely on a combination of automation technologies and human interaction, making it essential for engineers to have a deep understanding of both electrical engineering and electronics.

Some examples of control systems commonly found in the marine industry include:

- Propulsion control: Ships use complex electrical systems to control their propulsion, adjusting the power output and speed as needed. These systems need to be highly responsive and reliable to ensure safe and efficient navigation.

- Power distribution: As the demand for electric power on ships continues to increase, marine engineers need to design efficient and robust power distribution systems, often using advanced power electronics conversion methods.

- Safety systems: Electrical and electronic control systems are responsible for monitoring and managing various safety features on ships, such as fire detection, alarm systems, and automated shutdown procedures.

Marine Electronics

Marine electronics encompasses a wide range of devices and systems used on ships and offshore platforms, including communication systems, navigation equipment, and entertainment systems. These electronics need to be highly reliable, resistant to harsh marine environments, and able to operate under different conditions.

Here are some key aspects of marine electronics engineering:

- Communication systems: Ships use a variety of communication systems for both internal and external communication, such as satellite phones, radio equipment, and intercom systems. These systems need to be designed to ensure clear, reliable communication, even in challenging situations or poor weather conditions.

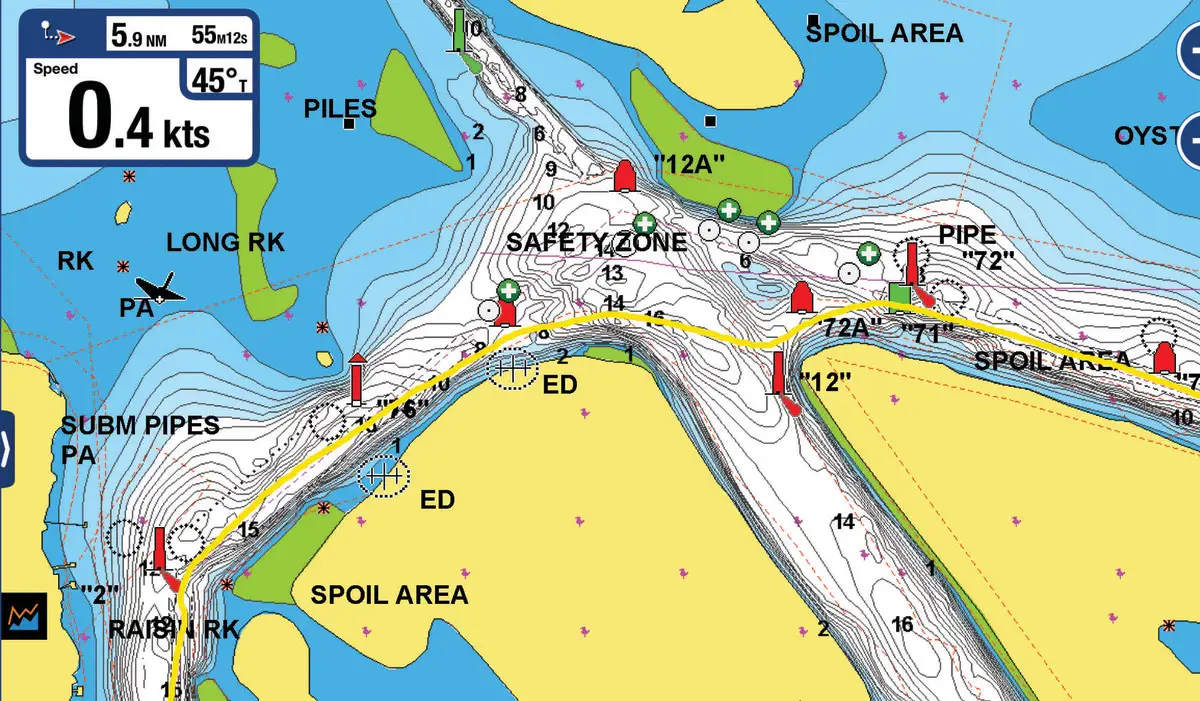

- Navigation equipment: Advanced electronics are used in navigation systems, such as GPS, radar, and electronic chart systems. These systems are critical for safe and accurate navigation, and marine engineers must have in-depth knowledge of how they function and interact with other systems onboard.

- Lighting and entertainment systems: Ships also rely on electrical and electronic systems for passenger comfort, such as lighting, air conditioning, and entertainment. These systems must be energy-efficient, durable, and user-friendly.

In conclusion, electrical and electronics engineering are integral components in the marine industry, influencing the function and safety of control systems and various electronic devices. Marine engineers need a strong understanding of these fields to ensure the efficient, safe, and comfortable operation of ships and offshore platforms.

Safety and Regulatory Compliance

Safety Protocols

Marine engineering focuses on ensuring the safety of all crew members and the operational efficiency of the vessels. A chief engineer is responsible for implementing safety protocols and procedures in accordance with national and international regulations. These protocols cover emergency situations, maintenance procedures, and risk assessments to minimize accidents and injuries.

Some of the critical safety measures include:

- Regular safety drills and training sessions for the crew

- Proper maintenance of machinery and equipment

- Implementation of fire prevention and control measures

- Ensuring effective communication among crew members

Engineering Regulations

Engineering regulations in the marine industry aim to maintain the high safety standards and compliance with national and international maritime laws. A ship engineer is responsible for adhering to these regulations and ensuring that the vessel operates within the mandated safety parameters.

Some of the essential regulations in marine engineering are:

- International Convention for the Safety of Life at Sea (SOLAS): This international maritime treaty focuses on ensuring the safety of crew members, passengers, and cargo aboard ships.

- International Maritime Organization (IMO) guidelines: IMO guidelines provide the regulatory framework for the safety and environmental aspects of marine engineering.

- National Regulations: Engineers must comply with the specific national regulations of the country in which they are operating, such as the Norwegian regulations for safety barriers in structural and marine engineering.

Junior engineers and third assistant engineers play a crucial role in sustaining safety and regulatory compliance. They assist the chief engineer in executing safety protocols and maintaining systems in compliance with engineering regulations. This collaborative approach ensures a safer and more efficient maritime environment, benefiting both crew members and the marine industry as a whole.

Onboard Systems and Component Management

HVAC Systems

Marine engineering systems are vital for the operation and comfort of a vessel. Among these systems, HVAC (Heating, Ventilation, and Air Conditioning) plays a crucial role in ensuring a healthy and comfortable living environment for the crew. A marine systems engineer is responsible for designing, installing, and maintaining these HVAC systems to ensure optimal performance.

A vessel's ventilation system is responsible for providing fresh air, controlling humidity, and removing contaminants such as engine exhaust and cooking fumes. This is crucial to ensuring safety and comfort onboard. Components such as air filters and air conditioning units should be regularly maintained and checked by the marine engineer for damage or obstructions.

On the other hand, a ship's air conditioning system ensures proper temperature control, dehumidification, and air distribution. Maintaining temperature in different spaces on board, such as the bridge, engine room, and living quarters, is an essential aspect of proper marine engineering.

Fuel and Energy Distribution

Another vital aspect of marine engineering is the management of fuel and energy distribution systems. A properly designed fuel system enables efficient and safe fuel storage, transfer, and consumption. Moreover, appropriate energy distribution ensures that all onboard equipment, from navigation to essential components like steering, receives adequate power to function.

In maritime engineering, the fuel system should account for primary fuel sources, such as marine gas oils or heavy fuel oils, as well as backups and emergency fuels. Proper storage, transfer, and pipeline systems are crucial. Regular inspections and maintenance of fuel filters, lines, and storage tanks help prevent potential hazards and enhance efficiency.

Energy distribution in a marine environment involves managing various power sources, such as diesel generators, battery banks, and shore power connections. A skilled marine engineer should be adept at selecting the right power sources and designing an efficient and versatile electrical distribution system. This requires a deep understanding of the vessel's components and its energy demands.

Effective management of marine engineering systems, including HVAC systems and fuel and energy distribution, is indispensable for a vessel's safe and efficient operation. Proper planning, design, installation, and maintenance by a knowledgeable marine systems engineer ensure that all onboard components function as intended, resulting in a secure and comfortable voyage.

Specialized Fields within Marine Engineering

Marine engineering is a diverse field that comprises various specialized areas, each focusing on specific aspects of design, construction, and operation of marine crafts and structures. Two notable specialized fields within marine engineering are Naval Engineering and Ocean Engineering and Offshore Technology.

Naval Engineering

Naval engineering encompasses the design, construction, and maintenance of sea-faring vessels for the navy and other military applications. This field directly involves naval architecture, which focuses on the shape, structure, and stability of naval vessels. A primary area of interest in naval architecture is designing and optimizing the hydrodynamic performance of a vessel, including its resistance, propulsion, maneuverability, and fuel efficiency.

Naval engineering includes the development of a variety of vessel types, such as:

- Submarines: These underwater vessels are designed for stealth and efficient underwater operations. They are typically used for military purposes such as reconnaissance, surveillance, and direct combat.

- Surface combatants: Including destroyers, frigates, and corvettes, these are specialized warships constructed for offensive and defensive capabilities.

- Aircraft carriers: These floating military bases can transport, launch, and recover aircraft, making them indispensable assets in naval warfare.

Ocean Engineering and Offshore Technology

Ocean engineering deals with the development and management of systems and structures in the marine environment to support various offshore activities. This field is highly interdisciplinary, involving elements of civil, mechanical, and environmental engineering. Typical applications of ocean engineering include the construction and operation of offshore platforms, subsea structures, and other marine facilities used in industries such as oil and gas exploration, renewable energy, and telecommunications.

Some key aspects of ocean engineering and offshore technology are:

- Offshore platforms: Fixed and floating structures for the extraction of oil, gas, and renewable energy resources from the ocean, such as drilling rigs, production platforms, and wind turbines.

- Subsea infrastructure: A complex network of pipelines, cables, and other equipment required to transport resources from offshore facilities to onshore processing plants and power grids.

- Coastal engineering: This subfield focuses on the design and construction of coastal structures, such as seawalls, breakwaters, and piers, to ensure the protection and management of coastal zones.

In conclusion, marine engineering features a wide array of specialized fields, with Naval Engineering and Ocean Engineering and Offshore Technology being among the most prominent ones. Professionals in these areas work on the cutting edge of technology, applying their expertise to the development and maintenance of sophisticated marine systems that impact both defense and civil sectors globally.

Infrastructure and Industry Applications

Maritime Infrastructure

Marine Engineering plays a vital role in the development of maritime infrastructure. This includes the design, construction, and maintenance of structures in coastal and offshore environments such as ports, harbors, and navigation channels. A well-developed maritime infrastructure is essential for the growth and sustainability of the global economy, as it facilitates the safe and efficient transportation of goods and people via sea routes. The integration of ecological principles with the design of marine infrastructure has become increasingly important, given its potential impact on the marine ecosystem.

Key components of maritime infrastructure include:

- Ports and harbors: Facilities designed to accommodate the loading, unloading, and storage of cargo, as well as the boarding and disembarking of passengers.

- Navigation channels: Pathways created for the safe and efficient passage of vessels through coastal and offshore waters.

- Breakwaters and seawalls: Structures constructed to protect shoreline installations and reduce the impact of waves and coastal erosion.

- Offshore structures: Facilities like oil and gas platforms, wind farms, and tidal energy converters, which harness natural resources at sea.

Shipyard Operations and Management

Shipyards play a crucial role in the maritime industry, providing a work environment for the production, repair, and maintenance of various types of vessels. These facilities ensure that the world's fleet of naval and commercial vessels is maintained efficiently and adhere to international safety standards. Effective shipyard operations and management are essential for the development of marine infrastructure and the advancement of the maritime industry as a whole.

Shipyard operations involve several key processes:

- Design and Engineering: Creating detailed plans and technical specifications for new vessels or retrofitting existing ones.

- Fabrication: Manufacturing components like hull sections, superstructures, and machinery that will be used for the vessel's construction.

- Assembly: The process of connecting fabricated parts, installing machinery, and outfitting the vessel with necessary equipment.

- Testing and Commissioning: Ensuring the vessel's systems and equipment meet design requirements and safety standards before delivery.

Shipyard management is responsible for overseeing these processes and ensuring a safe and efficient work environment leading to the development of modern vessels catering to the ever-evolving needs of the maritime industry. Their duties include enhancing production methods, resource allocation, and quality control measures, all of which are vital for the growth and success of the marine engineering sector.

Frequently Asked Questions

What are the core subjects studied in a marine engineering degree?

In a marine engineering degree program, students study a wide range of core subjects that provide a comprehensive understanding of the field. These subjects typically include fluid mechanics, marine structures, ship dynamics, naval architecture, thermodynamics, marine electrical systems, and oceanography. Additionally, specialized courses like underwater acoustics, corrosion and materials engineering, and ocean environment engineering may also be included in the curriculum.

What types of jobs are available in the marine engineering industry?

Graduates of a marine engineering degree program can pursue various job opportunities within the marine industry. Some common roles include naval architect, ship designer, marine surveyor, marine systems engineer, and offshore engineer. These professionals work on the design, construction, and maintenance of ships, submarines, oil rigs, and other marine structures, as well as their associated systems.

Which companies are leading employers in the marine engineering field?

There are numerous companies that specialize in marine engineering or employ marine engineers as part of their workforce. Some leading companies in the field include General Dynamics, Royal Dutch Shell, Rolls-Royce Marine, and Hyundai Heavy Industries. In addition, many engineering consulting firms, maritime academies, shipbuilding companies, and government agencies offer job opportunities for marine engineers.

What is the average salary range for a marine engineer?

The average salary range for a marine engineer varies depending on factors such as experience, location, and employer. In the United States, the Bureau of Labor Statistics (BLS) reported an average annual salary of around $93,000 for marine engineers and naval architects in 2020.

What educational qualifications are required to become a marine engineer?

To become a marine engineer, candidates typically need to have a bachelor's degree in marine engineering, naval architecture, or a related field. Some universities offer specialized programs in marine or ocean engineering, which focus specifically on the skills and knowledge required for a career in this field. Depending on the employer and job requirements, a master's or doctoral degree may be preferred for specialized or advanced roles.

How do the career prospects in marine engineering compare to other engineering fields?

The demand for marine engineers is expected to grow as new technologies continue to impact the marine engineering industry. According to the BLS, employment prospects in the field of marine engineering and naval architecture are projected to grow 1% from 2020 to 2030, slightly slower than the average for all occupations. However, the critical role of marine systems and structures in the global economy ensures that qualified marine engineers will continue to be in demand across various industries.

Footnotes

- Gas Turbines in Naval Propulsion ↩

- Marine Propellers and Propulsion ↩

- Propulsion Drive Models for Full Electric Marine Propulsion Systems ↩

- Techno-Economic and Environmental Assessment of Wind-Assisted Marine Propulsion Systems ↩

Meet Charlie Hardcastle, the undisputed king of the sea, and Editor-in-chief of Sea Magazine. Charlie's passion for boating runs deeper than a kraken's lair, and his years of experience on the water make him the ultimate boating guru. When it comes to boats, Charlie's knowledge is as vast as the ocean. He knows everything from the latest technology to the best locations for water enthusiasts. But Charlie's expertise isn't just limited to boating mechanics and history. He's also a marketing whiz, with a keen understanding of how the industry is adapting to changing consumer preferences. He knows how to effectively reach new audiences, whether they're looking for a luxury yacht or a modest pontoon boat. In short, Charlie is the complete package, a one-stop-shop for all things boating. So if you're looking to learn about the latest technology, marketing strategies, or just want to hear some epic sea tales, Charlie Hardcastle is your guy.