Transom Boat: Essential Tips for Maintenance and Safety

Transom boats are an essential part of the boating world, providing stability and support to various watercraft. The term "transom" refers to the flat, vertical structure located at the stern (rear) of the boat, connecting the side hulls and offering a place to mount engines or other equipment. This often-overlooked component plays a significant role in the overall performance and efficiency of a watercraft, as well as its durability and adaptability for various uses.

Understanding the different types of transom boats and their components is crucial for boat enthusiasts and owners. Various sizes and specifications correspond to specific needs and applications, while proper maintenance and repair contribute to a boat's longevity. Additionally, boat transom modifications can further enhance watercraft performance, making it crucial for individuals to realize the potential benefits and options available.

Key Takeaways

- Transom boats possess a critical structural component that supports the boat's stern and motor mounting.

- Different types and sizes of transom boats cater to diverse requirements and applications.

- Proper maintenance, repair, and potential modifications help to optimize a transom boat's performance and longevity.

Understanding the Terminology

When discussing boats and their various components, it's essential to understand the terminology surrounding them. One key term to be familiar with is the transom, a structural component found at the rear or stern of a boat. This part of the boat, usually formed of wood or fiberglass, serves as a flat, vertical surface connecting the vessel's hull, providing form and structure. The transom on a boat has multiple functions, including supporting the outboard motor and acting as a mounting point for other equipment.

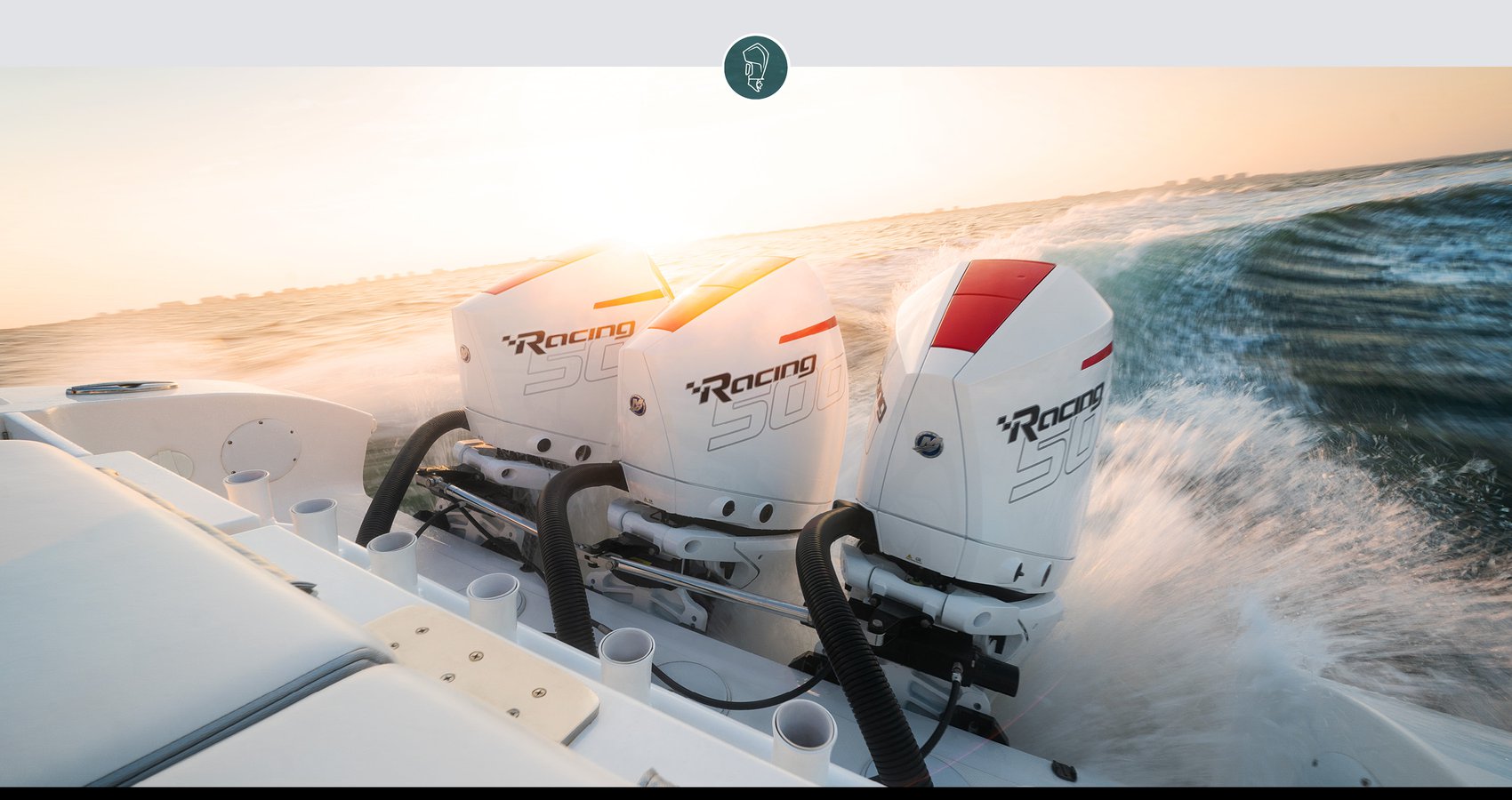

Outboard motors are distinct from inboard motors and serve as a primary means of propulsion for many boats. The outboard motor mounts directly to the transom using a transom plate, which helps distribute the motor's weight evenly across the transom's surface. While outboards are commonly found on smaller vessels, inboards are typically seen on larger boats, where the engine sits within the hull.

In addition to the motor, a transom may support setback brackets, which aid in creating additional space between the motor and the hull, reducing drag and enhancing boat performance. The terminology related to a boat's transom could also include various types of transoms found on different kinds of vessels. A full transom is one that extends all the way across the boat, while a euro transom features a more open design with a platform, often seen on offshore boats and catamarans. Other unique transoms include the canoe stern, which tapers and comes to a point, resembling the end of a canoe.

The transom also aids in dictating the boat's course, as the rudder, another essential component, is located near the transom. The rudder acts as a steering device essential for determining the boat's direction in the water.

Understanding this terminology is crucial for grasping the various aspects of a boat's construction and functionality. The rear of the boat may also be referred to as the aft, and it's imperative to be familiar with other terms such as port (left side when facing forward) and starboard (right side when facing forward). Since saltwater can cause some damage, such as rot on wooden transoms, it's essential for boat owners to understand the materials used in constructing transoms and options for maintenance and repair.

In conclusion, the transom is a vital component of a boat, encompassing various terms, designs, and components. By understanding this terminology, you can better appreciate the structure and performance of different boat types and effectively maintain and care for your vessel.

Types of Transom Boats

Different types of boats have varying transom designs to serve specific purposes. Transoms are an essential part of the boat structure, providing reinforcement and stability to the stern. Let's explore some popular transom boats and their unique features.

Fiberglass boats are commonly used for recreational activities and often have full or cutaway transoms. A full transom is a solid structure closing off the entire stern of the boat, while a cutaway transom has an opening to allow more water access and easier boarding. Fiberglass is a preferred material for constructing boats because it is lightweight, durable, and relatively easy to maintain.

Bay boats are designed for inshore fishing in protected shallow waters. They typically feature a reverse transom, which slopes backward from the waterline to the top edge. This transom type improves the boat's appearance and creates additional space on the aft deck.

Sailboats come in various sizes and designs, with transoms being an essential component to support the vessel's rigging. Traditional sailboats have a vertical transom, while more modern designs utilize reverse or cutaway transoms. The choice of transom design depends on the desired performance, stability, and overall aesthetics of the sailboat.

Catamarans are twin-hulled boats known for their stability, speed, and ample deck space. Some catamarans feature innovative transom designs such as the sea gate, which is a retractable transom that disappears into a recess in the deck when lowered. This feature enhances the boat's versatility, allowing for easy access to the water and on-boarding of passengers or equipment.

Boat owners have various options for transom materials, such as aluminum, fiberglass, and wood. This choice depends on factors like budget, maintenance requirements, and personal preferences. Each material offers its benefits and drawbacks, so considerations like durability, corrosion resistance, and upkeep costs should be weighed.

Fishing boats often have customized transoms to cater to specific angling needs. For example, some boats have integrated live wells or bait stations in the transom. Additionally, transom-mounted engines are popular in fishing boats as they provide power while reducing water resistance for better maneuverability and fuel efficiency.

In conclusion, transom boats come in diverse designs and materials tailored to meet specific needs of boat owners, be it for recreational sailing, inshore fishing, or speedy catamaran cruising. Understanding these various types and their benefits will help potential buyers make informed decisions when purchasing a boat.

Transom Boat Components

A boat transom is an essential component of a vessel's structure, located at the stern or the rear part of the boat. This structural element connects the two sides of the hull and forms the boat's aft end. Transoms serve several vital functions, providing essential stability and support to the hull and stern sections.

Typically, transoms appear as a flat, vertical surface that varies in size and shape depending on the boat's design. The angle of the transom, whether it's upright or slantwise, depends on the required structural system and the dimension of the watercraft. Although they are usually vertical, they may not always have ideal angles.

Transoms play a crucial role in helping to distribute different stresses and forces that the vessel might experience. Some boats may have additional components, such as a transom bracket or a transom plate. A transom bracket is a device that connects the outboard motors to the boat's hull in a secure, balanced manner. This alleviates stress and ensures proper alignment. In contrast, a transom plate reinforces the transom area to protect it from rapid water flow, reducing the risk of damage from turbulence or impact.

One specific area that connects the transom with the boat's interior is the splashwell. A splashwell is a recessed compartment designed to channel water away from the boat's engine and other critical components. This prevents water intrusion and potential damage to the vessel's electrical systems and mechanical parts.

In conclusion, the various components that make up a transom contribute significantly to a boat's structural integrity and performance. From reinforcing the hull and stern to protecting crucial mechanisms, these components work together to ensure the boat's safety and efficient operation while navigating various water conditions.

Maintenance and Repair

Maintaining the transom of a boat is crucial to ensure its safety, reliability, and structural integrity. Proper care and timely repairs play a vital role in preventing severe damage over time. Boat owners should regularly inspect and perform necessary maintenance activities to keep the transom in good condition.

One of the first steps in maintaining a boat's transom is regular inspection. Owners should check for signs of damage, such as cracks, water leaks, and stress marks, especially around the waterline. Also, inspecting the mounting areas of the engine, brackets, and bolts is crucial to ensuring the transom's safety. Look for any signs of wet areas, as this may indicate leaking issues that can compromise the structure.

Reinforcement of the transom can be necessary in some cases, where added strength is needed to support the boat's weight or heavy equipment. A transom saver can be a useful tool to support and distribute the weight of the boat and its engine while on a trailer. It prevents direct stress and tension on the transom, reducing the chances of cracks and damage.

When it comes to repairing the transom, it is essential to assess the extent of the existing damage. If there are noticeable cracks, rotting wood, or signs of significant damage, replacement or professional repair might be necessary. Small repairs, like tightening screws or patching leaks, can often be performed by boat owners themselves. However, for complex damage, seeking the help of a qualified boat repair shop or certified marine technician is highly recommended.

Proper boat maintenance is vital in preventing water leaks and other issues related to the transom. Ensure that the boat is well cared for, regularly cleaned, and that any water leaks are addressed promptly. Timely maintenance efforts can prolong the life of the boat's transom and prevent costly repairs or replacements in the future.

In conclusion, the transom is a critical component of any boat, and proper maintenance and repair are necessary to maintain the boat's overall performance and safety. Boat owners should regularly inspect the transom for any signs of damage, reinforce weak areas, and address repair needs in a timely manner to ensure a long-lasting and enjoyable boating experience.

Transom Boat Sizes and Specifications

Transom boats come in various sizes and specifications to cater to different boating needs. The primary factor to consider when examining a boat transom is its height. A boat's transom height is determined by the distance between the bottom of the boat hull and the top of the transom. Transom height is crucial for supporting the motor and ensuring optimal performance. It is typically measured in inches, and common transom heights include 33 to 35 inches for outboard engines capable of handling 50-70 HP.

Boat transoms are usually made of materials such as wood, fiberglass, aluminum, or steel, depending on the type of boat and intended usage. Among these materials, plywood is a popular choice for do-it-yourself builders due to its affordability and workability. Fiberglass and aluminum are often used in commercial boats for their durability and low-maintenance nature.

There are two main types of transom shapes: raked and rectangular. A raked transom slopes inward and upward from the waterline, while a rectangular transom remains vertical. Raked transoms are common in sailing and racing boats, as they reduce water resistance and improve aerodynamics. In contrast, rectangular transoms provide more stability and are typically found in powerboats and fishing vessels.

The boat transom width also plays a role in the boat's performance and compatibility with the motor. Transom width is important for the installation of push/pull cable steering systems, where a minimum width of 32.5 inches is generally required for a single motor setup.

Lastly, the boat transom size should correspond with the size of the engine that will be mounted on it. Overloading the transom with a motor that is too large can lead to structural instability and potential damage. It is essential to consult the manufacturer's specifications for the boat and engine to ensure a proper match.

By considering the height, materials, shape, and width of a boat transom, boaters can make informed decisions about the most suitable transom boat sizes and specifications for their needs.

Boat Transom Modifications

Boat transom modifications are often necessary for improving aesthetics, functionality, and safety. There are various ways to modify a boat's transom, depending on the desired outcome and the type of boat.

One common transom modification is the addition of an overhang. This can provide extra space for storage, seating, or fishing activities. Overhangs are typically constructed using sturdy materials like aluminum or fiberglass, and should be securely attached to the existing transom using mounting brackets and bolts.

Some boaters may want to add ladders or swim platforms to their transom, which can enhance recreational activities and make it easier to access the water. Before installing these accessories, it's essential to consider the load-bearing capacity of the transom, as well as the fastening points for the ladder or platform. Fittings such as mounting bolts, sealant, and brackets should be high-quality and corrosion-resistant to ensure a secure, long-lasting installation.

Mounting electronics or auxiliary motors are other common transom modifications. For instance, an angler may want to mount a fishfinder or trolling motor on their center console boat's transom. This requires selecting the appropriate mounting bracket that can support the weight and size of the equipment. The use of a transom saver, which is a support device designed to alleviate pressure and stress on the transom, is highly recommended for boats with larger outboard motors.

When modifying a boat's transom, it's crucial to ensure that all components, like mounting bolts, sealant, and brackets, are tightly secured and properly sealed. Any loose or exposed fasteners can cause damage and compromise the integrity of the modifications over time.

In conclusion, boat transom modifications can significantly impact a boat's functionality, appearance, and safety. By carefully considering the boat's structure, materials, and accessories, a successful modification can be achieved to enhance the boating experience.

Water and Transom Boats

Transom boats play a vital role in numerous water activities such as fishing, swimming, and access platforms. The transom, being the structural part of the boat furthest to the back, ties together with the keel and sides of the boat, making it an important component related to the water's interaction with the boat source.

The waterline is a crucial element in determining the performance and energy efficiency of a transom boat. When a boat sits in the water, the waterline indicates the point where water meets the hull. The waterline affects drag, which determines the boat's speed and fuel consumption. Lower drag results in improved boat performance and reduced fuel use.

Regardless of whether the boat is used in saltwater or freshwater, being a wet environment means it is essential to ensure water leaks are managed effectively. Boats are designed to handle water, but when leaks occur, they can cause serious damage to the transom, especially if the boat structure is made of wood. Proper maintenance, sealing, and inspection can help prevent such leaks and extend the lifespan of the boat source.

In saltwater environments, corrosion is a more significant concern due to the increased presence of salt which can corrode materials such as aluminum and cause oxidation in metals. Anodes should be checked and replaced when necessary to protect the boat's stern, transom, and outboard motor from corrosion source.

A reverse transom is a particular design that angles the transom from the waterline forwards. This design is featured in many modern fishing boats, often accompanied by sleek lines and curves that allow for reduced drag and increased stability while out on the water source. Fishing boats with reverse transoms enable better performance and handling, making them an attractive option for avid anglers and sportsmen.

In conclusion, the relationship between water and transom boats is significant, affecting the performance, stability, and maintenance of these vessels. With better understanding and proper care, boat owners can ensure their transom boats remain functional and efficient for a variety of water-based activities.

Transom Performance and Efficiency

Transom boats are designed to provide reinforcement and strength to a boat's stern and aft sections. The primary purpose of the transom is to offer support for the motor or stern drive, ensuring the stern does not become damaged or break due to the thrust and magnitude of the propulsion system. It is a critical component of any boat, not only ensuring structural integrity but also contributing to the vessel's overall performance and efficiency.

One essential aspect of transom boat performance is the angle of the transom. The transom angle can significantly impact a boat's stability, balance, and maneuverability. Additionally, the transom angle is vital for determining the ideal hull shape for optimal performance, with different shapes suited for displacement, semi-displacement, and planing hulls. The proper combination of transom type and hull shape can have positive effects on fuel efficiency, horsepower, and handling of the boat.

It is worth mentioning that various transom shapes influence performance and efficiency. For example, a full transom design creates a large surface area at the stern, increasing buoyancy and reducing drag. This design can lead to higher fuel efficiency and increased stability, which is especially beneficial for larger boats with higher horsepower engines. Additionally, a well-designed transom is crucial to prevent water ingress into the bilge, protecting the boat's components and ensuring its longevity.

In conclusion, understanding the relationship between transom performance and efficiency is crucial in ensuring a boat's optimal performance, fuel efficiency, and stability. By considering factors such as transom angle, hull shape, and boat size, boat owners can make informed decisions when selecting or modifying their vessels, ultimately enhancing their boating experience.

Frequently Asked Questions

What part of the boat is the transom?

The transom is the flat, vertical surface at the back of a boat that connects the two sides of the hull. It serves as a structural reinforcement at the stern of the boat and plays a vital role in both design and functionality. The transom can accommodate various attachments such as outboard motors or rudders depending on the boat's design source.

How to determine if a boat transom is damaged?

To assess if a boat transom is damaged, you need to inspect it for soft spots or discoloration that may indicate rot. If you suspect the transom is rotten, drill small holes into the area to check the extent of the rot source. Additionally, add a transom inspection to your boat maintenance routine to ensure that it stays in good condition over time.

What materials are used for boat transoms?

Boat transoms can be made from various materials, depending on the boat's design and purpose. Common materials include wood, aluminum, and fiberglass. Wood has been traditionally used for transoms, but modern boats often use aluminum or fiberglass due to their resistance to rot, maintenance requirements, and better overall durability.

What is the cost of repairing a boat transom?

The cost of repairing a boat transom depends on several factors, including the extent of damage, type of material, and labor expenses. It's essential to get an accurate estimate from a qualified professional before undertaking any repair work. Depending on the factors mentioned above, the cost of repairing a boat transom can range from a few hundred dollars for minor repairs to several thousands for a complete transom replacement.

What are the types of transom used in boats?

There are primarily three types of transoms used in boats: full transom, notched transom, and euro transom. Full transom boats extend all the way across the boat's stern, providing increased support and space for mounting accessories such as outboard motors or swim platforms. Notched transoms have a central cutout in the lower portion to accommodate outboard engines and offer better handling and speed. Euro transoms, also known as reverse transoms, slope backward and downward, providing easier access to the water and an aesthetic appeal to the boat design.

Difference between stern and transom?

The stern is the rear part of the boat, while the transom is the vertical surface at the rear that connects the two hull sides. The transom is a structural reinforcement that strengthens the stern area of the boat source. Both the stern and transom are essential components of a boat, with the transom being an integral part of the stern structure.

Charlie is Editor-in-Chief of Sea Magazine