How to Avoid Electrical Issues While Boating: Expert Tips and Guidelines

Boating can be a fun and relaxing activity, but it is important for enthusiasts to prioritize safety and address potential hazards. One common area for problems in boating is the electrical system, which, when not properly maintained or used, can cause numerous issues ranging from simple malfunctions to fires and electrocutions. Understanding how to avoid electrical issues while boating helps ensure a safer and more enjoyable experience on the water.

Various factors contribute to electrical problems in boats, such as loose connections, corroded wires, lack of proper maintenance, and the use of substandard equipment. Fortunately, there are measures one can take to prevent these problems and minimize the risk of dangerous situations. With careful planning, regular inspections, and use of the correct materials, boaters can mitigate electrical issues and enjoy their time on the water without fear of impending electrical hazards.

Boaters should learn and incorporate useful tips in their routine maintenance, such as securing connections, protecting wiring from water damage, and using the proper wire connectors1. Prioritizing these precautions will not only prevent electrical problems but also extend the overall lifespan and performance of the boat's electrical system.

Understand Your Boat's Electrical System

It is essential for boaters to understand their boat's electrical system to avoid potential issues and maintain overall safety onboard. This section discusses the basic anatomy of an electrical system and types of marine electrical systems.

Anatomy of an Electrical System

A boat's electrical system primarily consists of the following components:

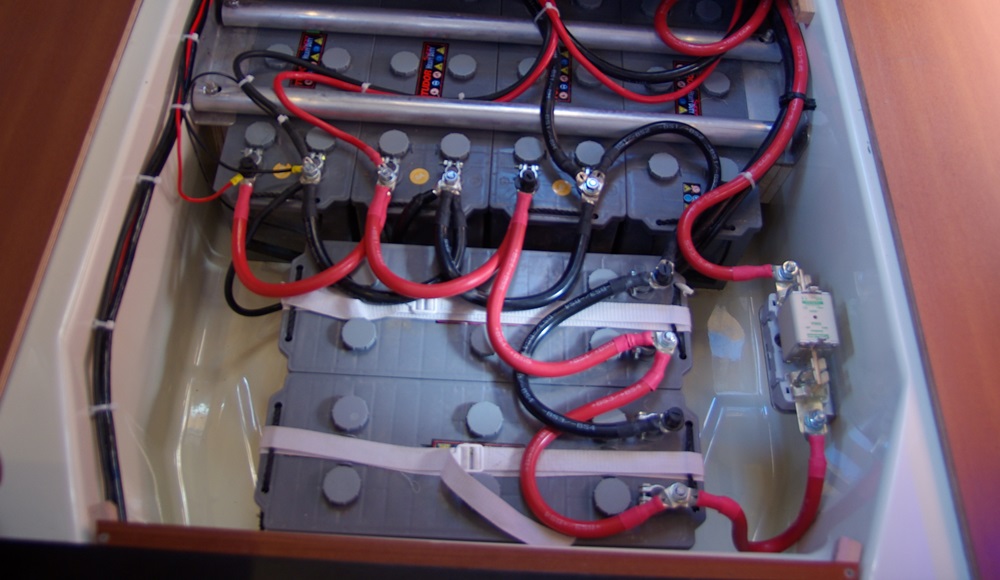

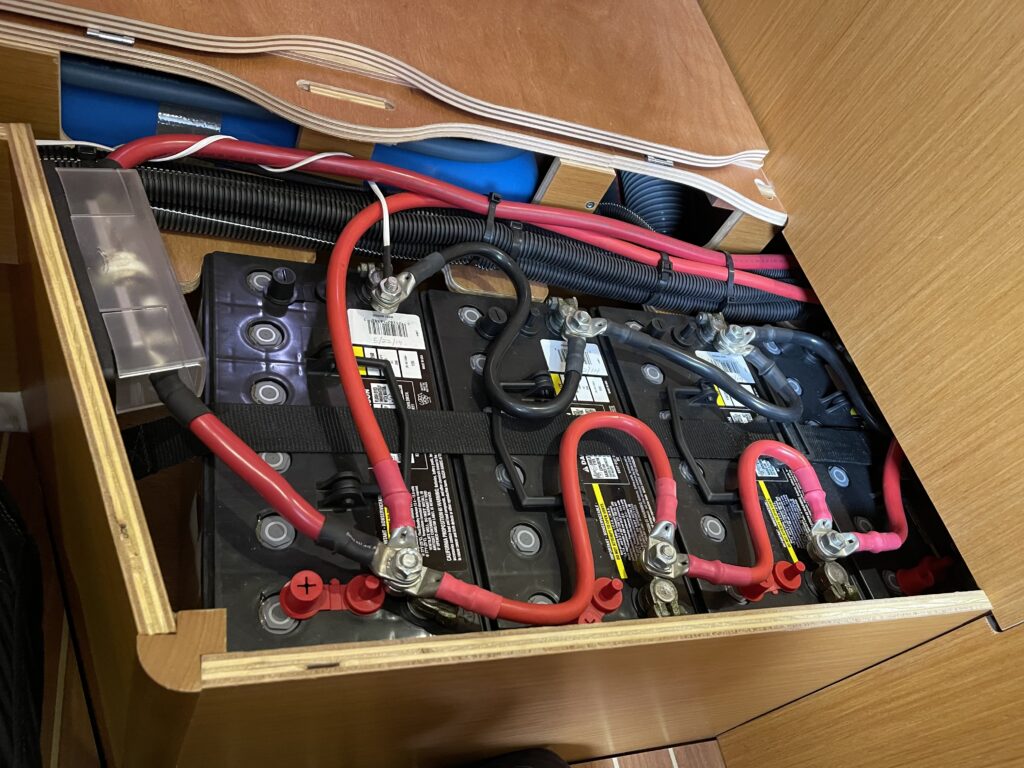

- Battery: Serves as the power source for the boat's electrical system, ensuring devices and equipment function properly when not onshore.

- Charging System: Recharges the battery when the engine is running or when connected to shore power. Examples include alternators and battery chargers.

- Wiring and Circuit Protection: Proper wiring, connectors, and protection devices (like fuses and circuit breakers) are crucial for maintaining the system's health and preventing electrical issues.

- Distribution System: Consists of switches and panels that control the electrical flow to devices and equipment.

Maintaining, repairing, and monitoring these components is crucial for avoiding electrical issues, ensuring your boat runs smoothly and safely during your trips.

Types of Marine Electrical Systems

There are two common types of marine electrical systems:

- Direct Current (DC) System: Typically powered by a battery or multiple batteries, a DC system supplies power to the boat's vital components, including navigation, lighting, communication, and essential appliances.

- Alternating Current (AC) System: Commonly known as shore power, an AC system supplies power to the boat while it is docked or attached to a generator. This system can power larger appliances and air conditioning units, among other things.

Understanding the basics of these systems and their respective components will help boat owners recognize potential issues and ensure a safer and more enjoyable boating experience. Proper maintenance and inspections will keep the electrical systems functioning optimally and reduce potential risks.

Perform Regular Inspections and Maintenance

Ensuring the safety and reliability of your boat's electrical system requires ongoing care and attention. This section outlines three key areas to focus on, helping you avoid potential electrical issues while out on the water.

Inspect Wiring and Connections

It is essential to regularly inspect your boat's wiring and ensure that all connections are clean, secure, and free of corrosion. This can prevent unexpected failures and potential hazards for the people on board. At least once a year, have a professional familiar with marine electrical codes perform a thorough examination of the electrical system (source). Keep an eye on the following:

- Visible wiring for wear and tear, such as cracks or exposed conductors

- Connectors and terminals for tightness and cleanliness

- Corrosion, particularly in areas subject to moisture and humidity

Check Battery Health

Always monitor the health of your boat's battery to avoid unexpected problems. A weak or dead battery can lead to numerous issues, including difficulties starting the engine or running onboard electronics. To ensure optimal battery performance:

- Clean and secure battery terminals

- Check electrolyte levels and top up with distilled water if necessary

- Charge the battery after each use to keep it topped up

- Perform periodic load tests and replace batteries as needed

Test Circuit Breakers and Fuses

Regular testing of circuit breakers and fuses can help protect against electrical overloads and potential hazards. Be vigilant for the following:

- Ensure your boat is equipped with the correct type and size of fuses and breakers

- Test circuit breakers and GFCIs periodically to verify they're functional and responsive

- Replace any faulty, broken, or incorrect fuses and breakers immediately

- Always carry spare fuses and breakers onboard as a precautionary measure

Use Proper Equipment

Ensuring a safe and reliable electrical system on your boat requires using proper equipment. This section covers two important aspects to consider when selecting components: marine-grade electrical components and Ground Fault Circuit Interrupters (GFCIs).

Marine-Grade Electrical Components

Using marine-grade electrical components is essential for avoiding electrical issues while boating. Marine components are specifically designed to withstand harsh marine environments and provide improved safety for all onboard systems. These components are typically more resistant to corrosion, moisture, and vibrations than their non-marine counterparts.

Some important marine-grade electrical components to consider include:

- Wiring and cables

- Fuses and circuit breakers

- Switches and outlets

- Battery terminals and connectors

By choosing marine-grade components, you can be confident in the durability and reliability of your boat's electrical system.

Ground Fault Circuit Interrupters (GFCIs)

Ground Fault Circuit Interrupters (GFCIs) are essential safety devices that protect against electrical shock by monitoring the flow of electricity and detecting any differences between incoming and outgoing current. If an imbalance is detected, the GFCI quickly cuts off power to the affected circuit, preventing potential injury or damage to the boat.

Installing GFCIs on your boat can significantly reduce the risk of electrical issues, particularly in high-risk areas such as:

- Galleys

- Heads

- Wet lockers

- Showers

By using proper equipment, such as marine-grade electrical components and GFCIs, you can greatly reduce the risk of electrical issues while ensuring a safe and enjoyable boating experience.

Follow Safe Boating Practices

Avoid Overloading Electrical Systems

One significant factor in preventing electrical issues while boating is avoiding overloading your boat's electrical systems. Distribute your electrical loads effectively by using separate terminal blocks, subpanels, or circuit breakers (Boating Mag). This will help maintain a stable voltage and reduce the risk of short circuits or other electrical problems.

Pay attention to the boat's maximum electrical capacity and do not exceed it. Ensure that all connections are tight, neat, clean, and away from water to minimize the risk of electric shocks, fires, or system malfunctions.

Properly Store Electrical Devices

Storing electrical devices correctly is essential in preventing electrical issues while boating. Keep all electronic devices in dry, well-ventilated spaces to minimize the possibility of water damage, rust, or corrosion.

Ensure all devices are well-secured to prevent them from moving during the voyage and causing potential damage to the electrical system. Chafed insulation is a leading cause of boat fires, so prevent chafing by using rubber padding, grommets, conduit, or wrapping with electrical tape (Boating Mag).

Inspect your boat's electrical devices regularly, and replace any damaged or worn-out components to maintain a safe and efficient system. Lastly, consider using waterproof covers or cases for your devices as an added layer of protection against water damage.

Implement Emergency Procedures

Know Your Breakers and Fuses

It is essential for boaters to familiarize themselves with their vessel's electrical breakers and fuses. This knowledge can help prevent and manage electrical problems while on the water. Regularly inspect your breakers and fuses for signs of wear, corrosion, or damage. Replace any faulty components as needed to ensure the safety of your boat's electrical system.

When on the water, it's important to know which breakers control which devices, as well as the proper procedures for resetting them. If you encounter an electrical problem, being able to quickly locate and address the issue can help minimize any inconvenience or potential hazards.

Reacting to Electrical Fires

Electrical fires can be extremely dangerous on boats, so being prepared and knowing how to handle the situation is crucial. To begin with, ensure that your boat has a sufficient number of appropriate fire extinguishers and that they are easily accessible. Regularly inspect the extinguishers to ensure they are functioning properly and within their expiration date.

If you experience an electrical fire on your boat, quickly turn off the power and disconnect the boat from any shore power connections. Use a fire extinguisher specifically designed for electrical fires (usually a Class C extinguisher) to put out the flames.

In addition to having proper fire-fighting equipment, proper preventative measures should also be taken. Keep electrical wiring a safe distance from engines and other heat-producing sources, and secure it to prevent it from coming into contact with water. Ensure that all electrical components, such as batteries and battery terminals, are properly covered to avoid accidental contact with water or other elements that could cause a fire.

Seek Professional Help

Periodic Boat Inspections

Ensuring the safety and longevity of your boat's electrical system is essential for a enjoyable boating experience. One of the best ways to do this is through periodic boat inspections. Having a professional marine electrician conduct a thorough inspection of your boat's electrical system can help you identify potential issues before they escalate into bigger problems. This can include checking your boat's wiring, connections, circuit breakers, outlets, and appliances.

Regular inspections are also an opportunity to detect outdated or corroded components that need replacement. Maintaining your boat's electrical system through regular inspections can help prevent malfunctions and avoid electrical issues while boating.

When to Contact a Marine Electrician

It's essential to recognize situations where professional help is necessary for the safety of your boat and its passengers. Below are some scenarios when you should contact a marine electrician:

- Installation of new equipment: If you're installing new appliances or electronics on your boat, a marine electrician can ensure proper installation while maintaining the integrity of your electrical system.

- After an electrical event: If your boat has experienced an electrical event such as a lightning strike, it's important to have a marine electrician assess and repair any damage.

- Unexpected power loss, flickering lights or intermittent power: These signs may indicate a potentially serious electrical problem that needs immediate attention from a marine electrician.

- Tripping of the shore power breaker: If the shore power breaker trips frequently, consult with a marine electrician to avoid potential electrical hazards.

Contacting a marine electrician when these situations occur can help ensure the safety and efficiency of your boat's electrical system. By seeking professional help, you can have peace of mind knowing your boat is prepared for any electrical challenges you may encounter while boating.

Charlie is Editor-in-Chief of Sea Magazine